Metal fabrication projects can be complex, and choosing the right cutting method can make all the difference. Understanding how fiber vs CO₂ laser cutting differs is essential. It’s safe to say that both technologies have shaped the industry for the better for years, but they operate fundamentally in different ways. These differences affect everything from precision and speed to cost and material compatibility. If you’re comparing capabilities or deciding which service better fits your needs, this guide breaks down the key contrasts clearly and practically.

How The Two Technologies Work

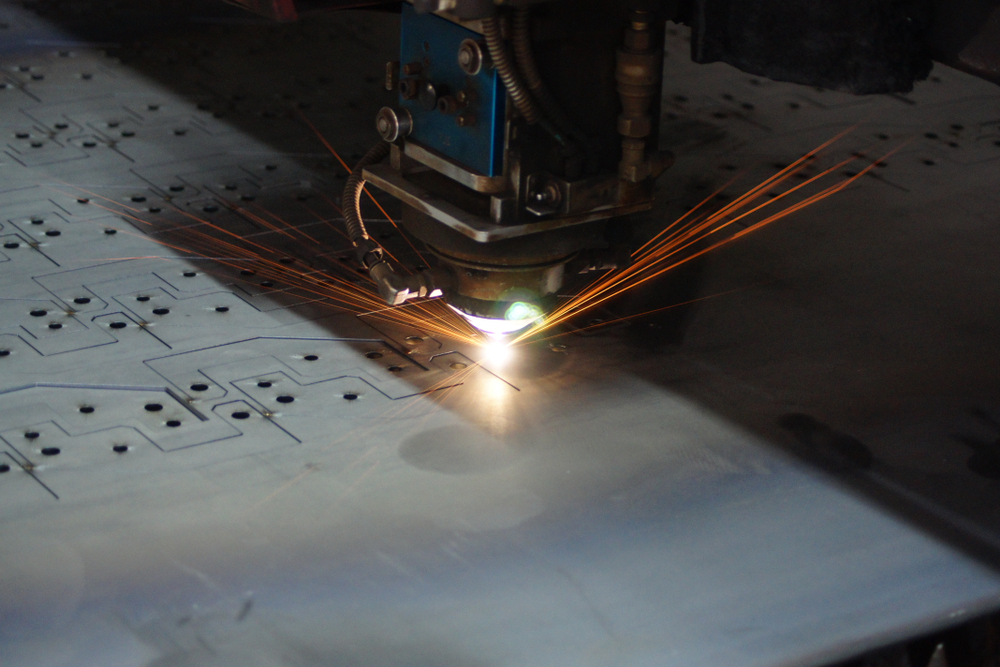

If you had to say the fundamental difference when comparing fiber vs CO₂ laser cutting, it would have to be how the two beams operate. Fiber lasers use solid-state diode technology, meaning light is pumped into a fiber optic cable where it becomes amplified. Then, it gets converted into a powerful, precise laser beam. The process is extremely efficient because it occurs within a sealed fiber system.

Conversely, CO₂ lasers work with a gas mixture (typically CO₂), nitrogen, and helium. Electricity excites the gas inside a sealed tube, producing the laser beam. It’s been a solid foundation for high-volume work output, but it naturally introduces more opportunity for energy loss and requires more mechanical components to keep the system running smoothly.

Efficiency and Operational Cost Differences

Energy efficiency and operational costs are other factors to consider when comparing fiber vs CO₂ laser cutting. Fiber lasers often have a clear advantage for several reasons. They are in a solid state and require no gas refills, and convert a much higher percentage of electrical energy into usable cutting power. CO₂ lasers typically achieve 10–15% efficiency, while fiber lasers can reach 30–40%. What does this translate to? Lower power consumption and reduced energy bills, which can be a top priority for shops cutting metal day in and day out.

It’s also important to consider maintenance when comparing fiber and CO₂ laser cutters. Fiber lasers often require much less maintenance. There are no gas tubes to replace, no mirrors to realign, and fewer moving parts overall. CO₂ lasers involve more downtime due to the upkeep of alignments, filters, and optics. The bottom line is that fiber laser cutting tends to cost less in the long run, even if your initial investment is higher. This is one of the reasons many fabrication shops have transitioned from CO₂ to fiber systems as their primary setup for metal cutting.

Material Suitability and Performance

One of the most important aspects of the fiber vs CO₂ laser cutting comparison is which materials each system handles best. Fiber lasers excel at cutting any type of reflective material. Some of these examples include:

- Copper

- Brass

- Aluminum

- Stainless steel

These metals can reflect the longer wavelength produced by CO₂ lasers, bouncing the beam away and potentially damaging the equipment. Fiber lasers are better for the materials listed above because they generate a much shorter wavelength, allowing the beam to be absorbed more effectively. Not only does it allow for better efficiency, but it’s also much safer.

CO₂ lasers still have their value in certain situations. One of the advantages they’re known for is the precise and smooth cuts they can achieve on thicker non-metal materials like wood, acrylic, and plastics. For teams working on a wide variety of materials (specifically non-metals), you can see the value that this type of laser would have. However, in a purely metal-focused comparison, the clear advantage goes to fiber lasers.

Precision and Speed: Where Fiber Laser Cutting Stands Out

When it comes to the bottom line, productivity is going to be a top priority. Fiber lasers consistently deliver faster speeds, especially on thin to medium sheet metals. They deliver a smaller, more concentrated beam spot. This tighter focus increases cutting efficiency and precision, allowing fiber machines to cut at dramatically faster rates compared to CO₂ lasers on the same material thickness. A good example of this is thin-gauge stainless steel. Fiber lasers would be able to cut that material type 2-3 times faster.

Positioning is extremely accurate because the beam is delivered through fiber optics. As a result, you’ll have the precise lines you need and tighter tolerances, which are imperative for different industries like manufacturing, aerospace, automotive components, and architectural metalwork. CO₂ machines can still produce excellent edge quality, especially on thicker materials and non-metals, but their speed and accuracy simply can’t match fiber systems in most metal-focused applications.

Fiber vs CO₂ Laser Cutting: Which Should You Choose?

Consider this quick guide below when making the choice between fiber and CO₂ laser cutting.

You should lean toward fiber laser cutting if:

- You’re cutting primarily metals

- You need high precision and fast turnaround

- You work with reflective materials like copper or brass

- Long-term operational cost and efficiency are priorities

CO₂ laser cutting may be better if:

- Your project involves thicker materials beyond metal

- You need exceptional edge finishes on non-metals

- Versatility across multiple material types matters more than speed

Metal Laser Cutting Services In Orem, Utah

Partnering with an experienced team ensures you get the right technology for your project’s materials, tolerances, and finish requirements. Professional shops understand how each system performs and can match your design with the ideal cutting method. For reliable, high-precision results, explore Cypress Metals’ expert Metal Laser Cutting Services.